- Home

-

Core Technology

Core Technology

-

Business

Business

-

Research and Manufacturing

Research and Manufacturing

-

About Us

About Us

Precision Removal of Dissolved Oils | Preferred Choice for oily liquids (wastewater) | Pioneering the "Reversible Adsorption-Cyclical Regeneration" Oil Separation Concept

The "ORZ High-efficiency Oil Removal Technology" and its core equipment, independently developed by Sino-Sci Columbus, specifically address challenges in deep oil removal and COD/TOC reduction for:

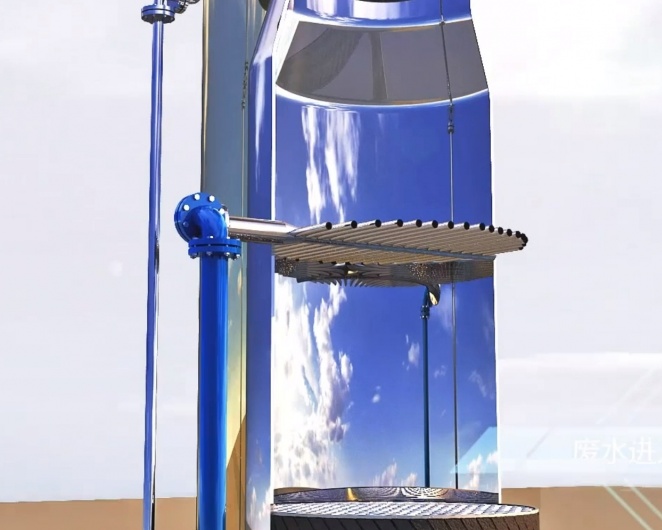

The ORZ process integrates three functional units: adsorption oil removal unit, desorption and regeneration unit, and desorption agent recovery unit, forming a closed-loop system that achieves zero-pollution objectives with high economic efficiency and environmental friendliness.

This technology has been implemented in over 10 demonstration projects nationwide, with an annual processing capacity of approximately 6.3 million tons of liquid feed/wastewater and a maximum single-system capacity of 1.31 million tons/year. Recognized with prestigious awards including the National Science and Technology Progress Award, National Key Encouraged Environmental Technology & Equipment, Yangtze River Water Protection Award, Leading Technology Pioneer in "Science Innovation China", Beijing New Technology Product Certification, and Carbon Footprint Certification.

The presence of recalcitrant oil contaminants in various forms (e.g., dissolved, emulsified, or suspended) within organophosphate extractant solutions (e.g., P204/P507) and organic wastewater containing oils/phenolic compounds leads to reduced product purity, quality degradation, and operational inefficiencies in evaporation systems.

We pioneered the groundbreaking concept of " High-efficiency Oil Removal – Reversible Adsorption – Cyclical Regeneration" and independently developed: ORZ-series amphiphilic surface-modified adsorption microspheres;The innovative ORZ Oil Removal Unit; Integrated optimization of core technologies.

Awarded 5 scientific and technological honors; Granted 23 invention patents and utility model patents; Certified with Carbon Footprint compliance (ISO 14067:2018 & PAS 2050:2011).

The system achieves an annual compliant wastewater treatment capacity of 6.3 million metric tons. Compared to traditional activated carbon-based systems, it reduces hazardous waste disposal costs by 70% - 90%, lowers annual operating expenses by 50% - 70%, and cuts carbon emissions by approximately 60%.

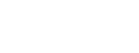

When oily wastewater/liquid feedstock passes through the ORZ Oil Removal Unit, van der Waals forces and molecular sieving functionality between the packing material and organic oil molecules enable the accumulation of large organic molecules on the packing surface, achieving oil-water separation. Upon saturation, the system regenerates the packing via the "like dissolves like" principle, where a desorbent dissolves and elutes the adsorbed oils, restoring the packing to an oil-free state. The "Novel Ethanol-Water-Oil Distillation System" then ensures efficient recovery and recycling of the desorbent and water, closing the operational loop.

Oil content

Primarily designed for organic phosphate extractants (e.g., P204, P507, C272, BC196) or oily wastewater.

Non-adsorption of inorganic substances, zero loss of raw materials and valuable metals.

Environmental-friendly technology

Enabling the resource recovery of ethanol, water, oil, etc., without secondary pollution such as hazardous waste.

The whole system has a high degree of automatic operation, which can realize "unmanned workshop"

High product purity and quality are achieved after oil removal

Avoid the abnormal operation of evaporation process due to bubbling of the material liquid.

Novel Heterogeneous Submillimeter-Scale High-Efficiency Separator

Desorption Agent Recovery Distillation System

Oil containing crystalline salt

Crystalline salt after oil removal

Distillation system recovers desorbent

Oil recovered by distillation system

Crystalline salt of activated carbon after oil removal

Crystalline salt after ORZ oil removal