- Home

-

Core Technology

Core Technology

-

Business

Business

-

Research and Manufacturing

Research and Manufacturing

-

About Us

About Us

International Advanced Technology | Preferred Ammonia-Nitrogen Wastewater Treatment Technology | Efficient Ammonia Resource Recovery

The Resource Recycling Treatment Technology of Ammonia-Nitrogen Wastewater developed by our company adopts a steam stripping-distillation process. Through breakthroughs in key technologies including chemical-enhanced thermal decomposition complexation-molecular distillation, high-performance specialized column internals design, high-temperature high-alkali anti-scaling dispersion technology, and full-process automatic monitoring systems, it achieves stable compliance of effluent ammonia nitrogen levels while recovering high-purity concentrated ammonia water, ammonium salts, or liquid ammonia as resources. The technology has been implemented in over 80 demonstration projects nationwide, including more than 20 industry-first application projects, effectively supporting clean production and green sustainable development in industrial sectors.

The steam stripping-distillation technology, recognized as a major achievement of China's National 863 Program and Water Special Project, has been awarded prestigious honors including the "National Technology Invention Award", "Environmental Protection Science & Technology Award", and "Science & Technology Progress Award". It has been repeatedly listed in key national catalogs such as the "National Catalogue of Encouraged Major Environmental Protection Technologies and Equipment" and "National Directory of Encouraged Environmental Protection Technologies". The technology has also received accolades including "National Key Practical Environmental Protection Technology", "Beijing New Technology & Product Certification", and was ranked among the "Top 100 Intelligent Environmental Technologies" on international platforms.

Heavy metal-ammonia complex ions exhibit high stability, posing significant challenges for efficient separation and resource recovery.

Developed the reactive distillation-enhanced thermal decomposition complexation distillation technology for deep decomposition of heavy metal-ammonia complexes; invented and developed core equipment including high-performance corrosion-resistant and anti-scaling steam stripping-distillation ammonia removal columns and single-step ammonia recovery units.

Granted 22 scientific and technological awards; 37 invention and utility model patents; in 2010, expert evaluations certified that the overall technology reached internationally advanced levels, with the anti-clogging integrated technology for high-concentration ammonia-containing wastewater treatment distillation towers and resource recovery effectiveness achieving internationally leading standards.

Each year, we treat 105 million tons of wastewater, reduce ammonia-nitrogen emissions by approximately 1.38 million tons, achieve a benefit of about 6.3 billion yuan from ammonia water recycling, and recover approximately 10 million tons of ammonia water, creating a total economic benefit of over 12.3 billion yuan for our customers annually

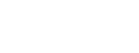

Leveraging the difference in relative volatility between ammonia and water, this technology employs thermodynamic calculations of gas-liquid equilibrium (ammonia-water), complexation-decomplexation equilibrium (metal-ammonia), and precipitation-dissolution equilibrium (metal hydroxides). In the stripping-distillation column, ammonia is separated as molecular ammonia from water, recovered as high-purity aqueous ammonia or liquid ammonia through condensation, and reused in production or sold commercially. Post-treatment ammonia nitrogen levels below 10mg/L enable direct discharge or industrial reuse. This integrated process achieves simultaneous deep ammonia removal, recovery of heavy metals/salts/water, and zero-discharge treatment of complex wastewater containing ammonia, heavy metals, and high salinity.

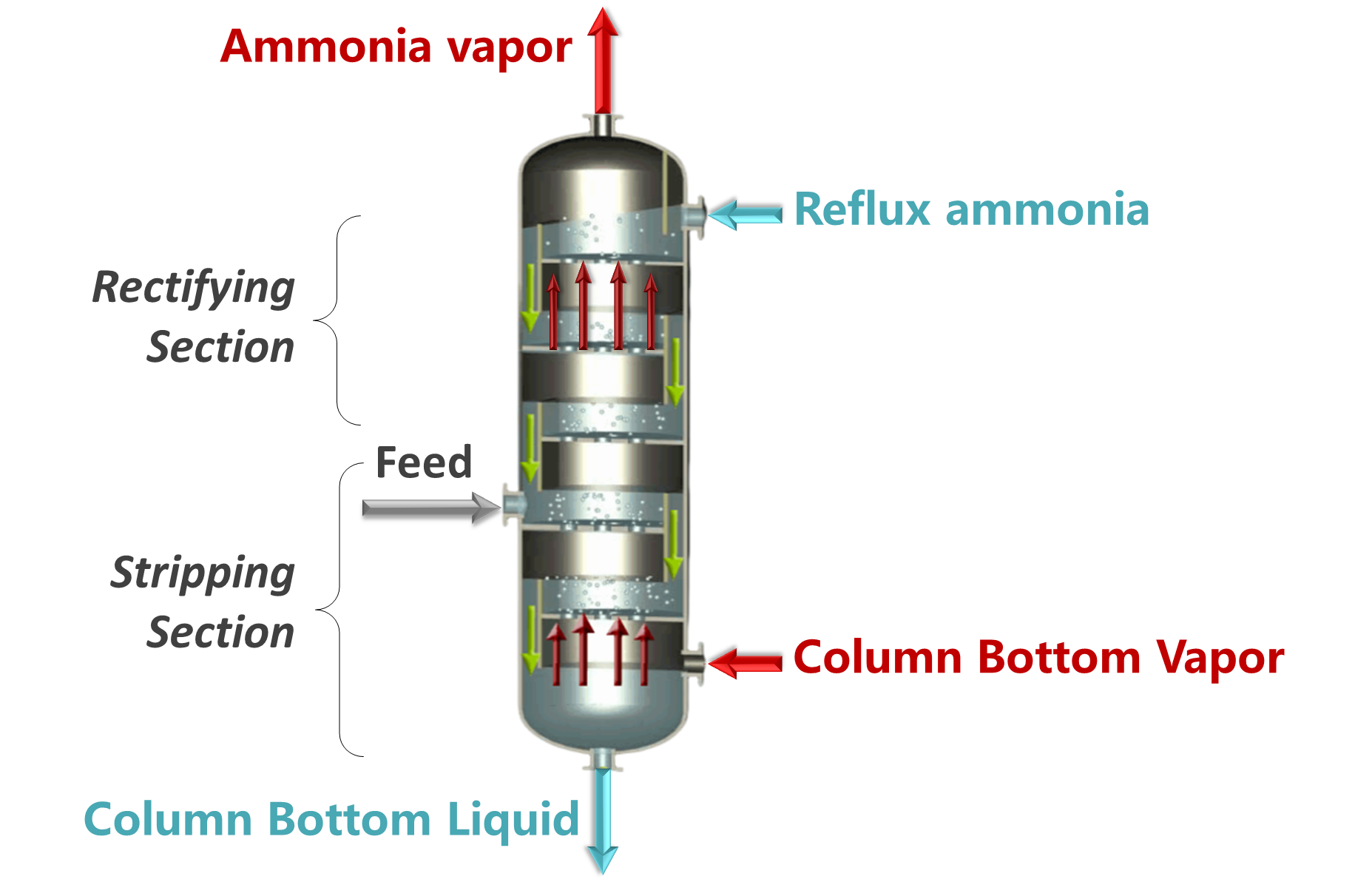

Through mathematical modeling and an integrated approach combining theoretical analysis, experimental validation, and demonstration projects, this methodology investigates mass transfer mechanisms of diverse materials in various deammoniation towers and develops industrial-scale designs. The tower's design parameters are derived from computational simulations of the complete deammoniation process.

Aspen Process Simulation

Supercomputing Capability

ammonia recovery rate

The ammonia recovery rate is ≥ 99.5%, recoverable 10% to 28% high-purity ammonia solution, ammonium salt products, or liquid ammonia

high ammonia-nitrogen removal efficiency

The ammonia nitrogen of wastewater treatment ranges from 1~70g/L as input density and to be discharged with less than 5mg/L in one step

One-step condensation directly recovers ammonia water, with high equipment integration and simple operation.

processing capacity

The system demonstrates high operational load elasticity through automatic processing capacity scaling between 60% and 120%.

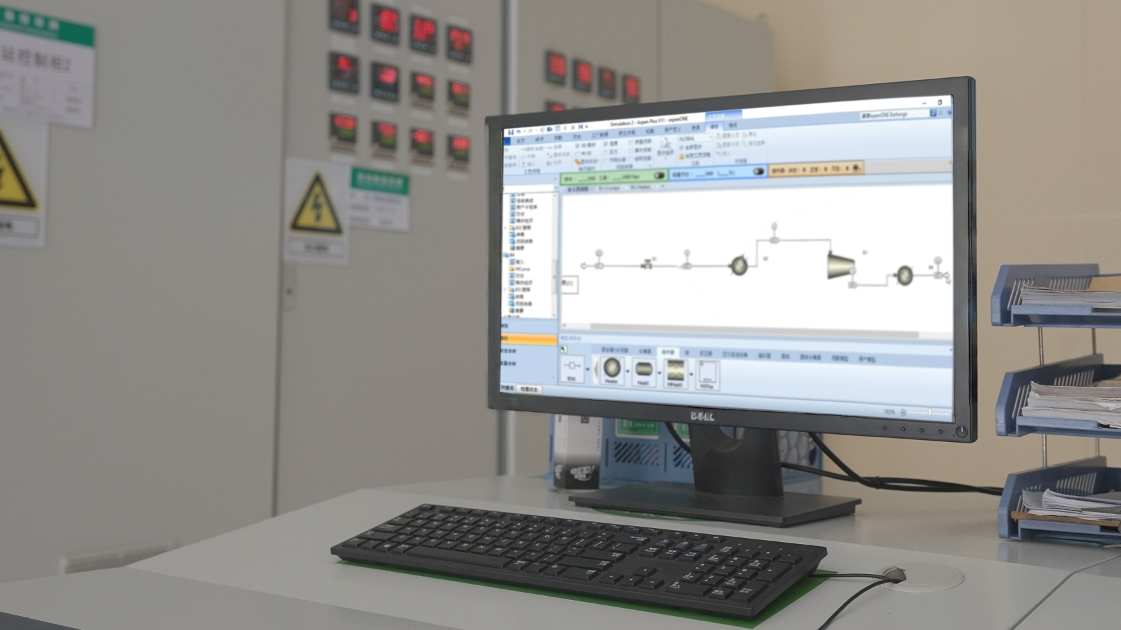

The stripping-distillation deammoniation tower features an application-specific design with precision-engineered internals, demonstrating exceptional anti-clogging, anti-scaling, and shock-resistant capabilities.

Stripping-distillation deammoniation tower

Precision-engineered internals structure of stripping-distillation tower

The system enhances operational efficiency and reduces manual operational costs through AI integration.

The AI control system comprises:PLC control systems,AI service modules,Aprol industrial control platform,

Cloud service infrastructure,Model training frameworks,Simulation environments.

Overall System Architecture

AI Training Workflow

Pioneers industry-first fully autonomous operation of self-learning AI systems

Pioneers industry-first fully autonomous operation of self-learning AI systems

Enables autonomous system regulation to maintain real-time optimal operating parameters, ensuring compliance while achieving minimal energy consumption

Enables autonomous system regulation to maintain real-time optimal operating parameters, ensuring compliance while achieving minimal energy consumption